Fasteners and Machining: Tailored Solutions for each Manufacturing Requirement

Browsing the World of Fasteners and Machining: Strategies for Precision and Speed

In the intricate world of fasteners and machining, the quest for precision and speed is a continuous obstacle that demands precise focus to information and strategic preparation. From recognizing the diverse array of bolt kinds to picking optimum products that can stand up to rigorous demands, each step in the process plays a crucial duty in attaining the wanted outcome.

Understanding Bolt Types

When picking bolts for a task, understanding the various kinds available is crucial for making sure optimum efficiency and reliability. Bolts are available in a vast array of kinds, each designed for specific applications and demands. Screws are made use of with nuts to hold materials with each other, while screws are flexible bolts that can be utilized with or without a nut, depending on the application. Nuts, on the other hand, are inside threaded fasteners that mate with screws or bolts, giving a safe hold. Washers are vital for dispersing the lots of the bolt and preventing damages to the material being fastened. Additionally, rivets are permanent bolts that are perfect for applications where disassembly is not required. Recognizing the distinctions between these fastener kinds is important for choosing the right one for the job, guaranteeing that the connection is strong, long lasting, and reliable. By selecting the proper fastener type, you can enhance the performance and longevity of your project - Fasteners and Machining.

Choosing the Right Products

Understanding the significance of choosing the appropriate materials is paramount in guaranteeing the ideal performance and integrity of the picked bolt kinds discussed previously. When it comes to bolts and machining applications, the material choice plays a vital duty in identifying the general toughness, toughness, rust resistance, and compatibility with the desired setting. Different products provide differing homes that can significantly influence the efficiency of the fasteners.

Typical materials used for bolts include steel, stainless steel, titanium, brass, and light weight aluminum, each having its one-of-a-kind toughness and weak points. Steel is renowned for its high stamina and toughness, making it appropriate for a vast variety of applications. Selecting the ideal material includes thinking about elements such as toughness demands, environmental problems, and budget restrictions to make sure the desired efficiency and durability of the bolts.

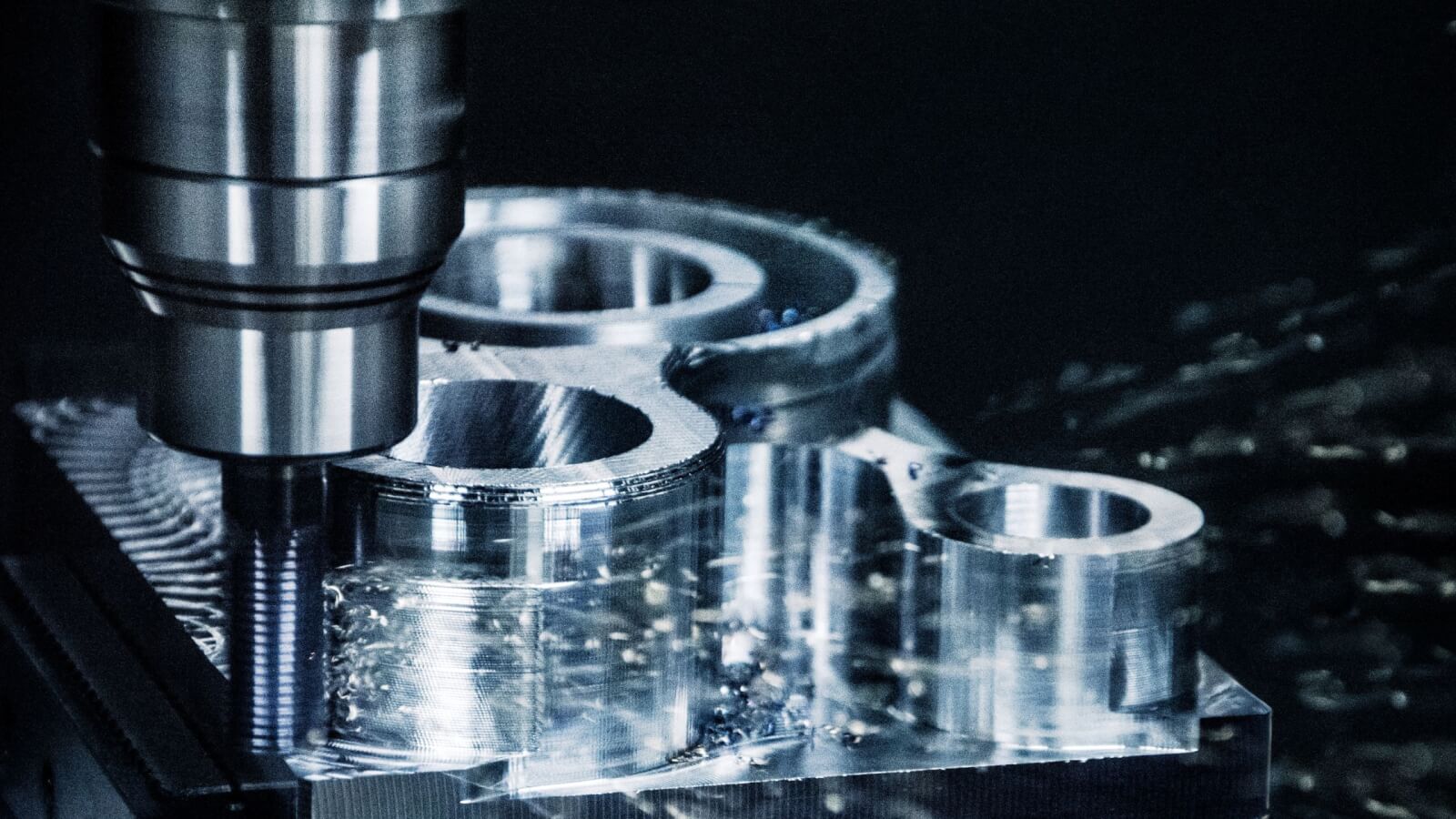

Precision Machining Techniques

In enhancement to CNC machining, other accuracy methods like grinding, transforming, milling, and drilling play essential roles in bolt production. Grinding assists attain fine surface area finishes and tight dimensional resistances, while turning is often used to produce cylindrical components with specific sizes. Milling and boring operations are necessary for shaping and producing openings in fasteners, guaranteeing they satisfy precise specs and feature correctly.

Enhancing Rate and Effectiveness

To maximize fastener manufacturing procedures, it is necessary to have a peek at this website simplify procedures and carry out reliable methods that match accuracy machining techniques. One vital method for improving speed and performance is the implementation of lean production concepts. By minimizing waste and focusing on constant enhancement, lean techniques aid eliminate bottlenecks and maximize operations. In addition, investing in automation modern technologies can dramatically increase production speed. Automated systems can take care of recurring jobs with precision and rate, permitting employees to focus on more complex and value-added activities. Taking On Just-In-Time (JIT) stock management can additionally enhance performance by guaranteeing that the ideal materials are readily available at the appropriate time, decreasing excess inventory and minimizing preparations. Fostering a society of partnership and interaction amongst use this link group participants can improve overall effectiveness by advertising openness, problem-solving, and innovation. By combining these strategies, makers can achieve an equilibrium in between speed and accuracy, inevitably boosting their affordable edge in the fastener industry.

Quality Assurance Procedures

Implementing rigorous quality assurance procedures is essential in making certain the reliability and consistency of bolt products in the manufacturing procedure. Quality control steps incorporate numerous phases, beginning with the option of raw products to the last evaluation of the completed fasteners. One fundamental facet of quality assurance is conducting extensive product assessments to verify compliance with specs. This involves analyzing factors such as product toughness, make-up, and sturdiness to ensure that the bolts meet industry criteria. In addition, keeping an eye on the machining refines is necessary to promote dimensional precision and surface finish top quality. Using sophisticated innovation, such as automated inspection systems and accuracy measuring devices, can boost the accuracy and effectiveness of quality assurance treatments.

Regular calibration of equipment and machinery is important to maintain uniformity in production and make certain that bolts fulfill the needed resistances. Executing stringent protocols for determining and resolving non-conformities or problems is vital in avoiding substandard items from entering the marketplace. By establishing a thorough Check Out Your URL quality assurance structure, producers can promote the online reputation of their brand and provide fasteners that fulfill the highest possible standards of efficiency and toughness.

Verdict

In the detailed world of bolts and machining, the quest for precision and speed is a continuous obstacle that requires thorough interest to information and critical planning. When it comes to bolts and machining applications, the material choice plays an essential role in figuring out the total stamina, sturdiness, rust resistance, and compatibility with the intended setting. Precision machining involves numerous sophisticated approaches that make sure the tight resistances and specs needed for fasteners.In enhancement to CNC machining, other accuracy strategies like grinding, turning, milling, and boring play vital functions in bolt manufacturing.To maximize fastener manufacturing procedures, it is important to improve procedures and execute efficient strategies that complement accuracy machining strategies.